Which of These Statements About Reverse Logistics Is Best

Which of these statements about reverse logistics is BEST. C Reverse logistics systems usually play no role in customer satisfaction.

Reverse Logistics 101 All Things Supply Chain

Remanufacturing and refurbishing can sometimes also be considered under reverse logistics.

. Reverse Logistics Best Practices Download this new whitepaper to learn how to calm the reverse logistics chaos by examining these Distribution Center DC best practices. Reverse logistics refers to any and all operations that relate to the reuse of materials and products. Warehouse in the News.

Types of racks and aisle configurations that can be used for returns areas. Reverse logistics is a doctrinal supply chain term describing how byproducts and other materi-als are returned through the original supply chain in order to recycle refurbish or ensure proper disposal. 3 Reverse logistics systems are usually less cost-efficient than forward-based systems.

Which of these statements about reverse logistics is BEST. Consider establishing a separate and dedicated division with its own profit and loss statement. Types Of Reverse Logistics.

Best Practices in Reverse. It is a method of moving a particular good for either understanding its value or to make proper disposal. Reverse logistics covers a range of processes.

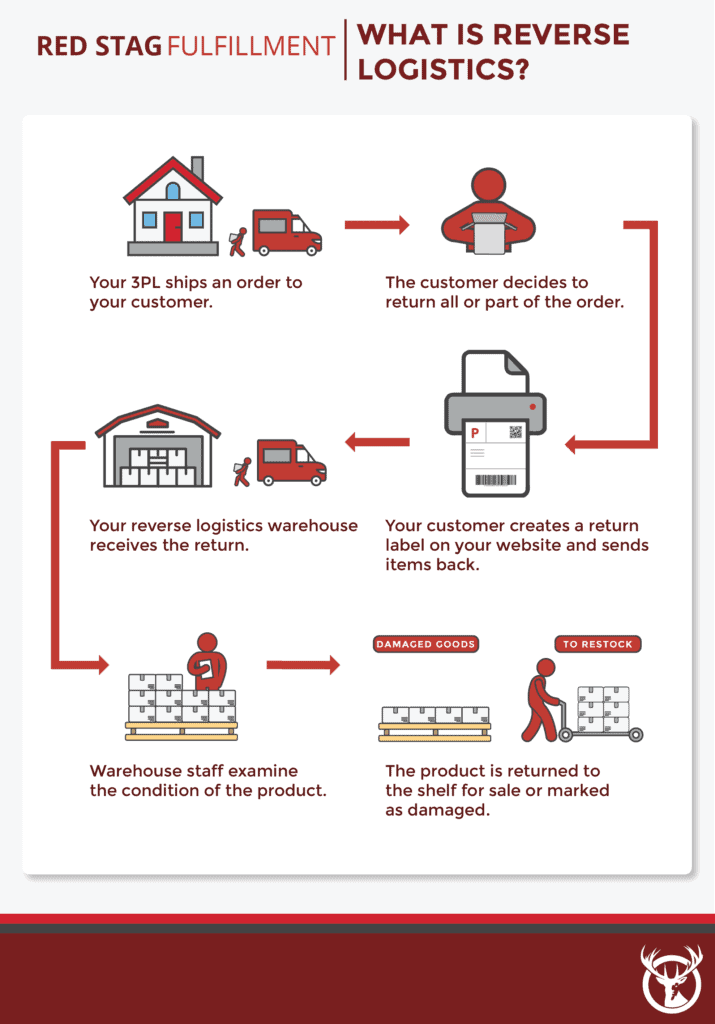

Which of the following statements is true regarding goods in a reverse logistics system. Reverse logistics is the process of reusing different products and materials. Savvy companies use reverse logistics to build customer loyalty and repeat business and to minimize losses related to returns.

A Reverse logistics systems are usually less cost-efficient than forward-based systems. Now that we understand the reverse logistics definition lets look at how it works. A Reverse logistics systems are usually less cost-efficient than forward-based systems Your new Garden Weasel fails to completely satisfy you so you decide to return it for a full refund.

Reverse logistics presents one of the biggest operational challenges in the world of e-commerce freight logistics due to the sheer volume and cost of processing returns. C They travel through the same terminals as the forward logistics system. D Little product information is required.

With reverse logistics accounting for nearly 1 of the total US. Have senior-level accountability for the entire reverse logistics process. A great example of a business that uses reverse logistics is Oco Meals which offers a zero waste meal delivery service to customers across the greater Vancouver area of Canada.

Successful Examples Of Reverse Logistics. How to think about workflow steps such as unloading staging and triage. Over the past five years the Department of Defense has shifted from a stovepipe approach to logistics functions to a more holistic supply chain management approach.

Gross domestic product it is not surprising that this process defined as the return exchange repair refurbishment remarketing and disposition of products is quickly emerging as an integral component in leading. Best Practices In Reverse Logistics. 22 A Reverse logistics systems usually play no role in customer satisfaction.

Subscribers to Supply Chain Management Review and members of RLS and WERC. C Reverse logistics systems are usually less cost-efficient than forward-based systems. But it also can come with a troublesome side effect.

1 Reverse logistics systems are usually designed to be less flexible than forward-based systems. Which of these statements about reverse logistics is best. Unlike the forward logistics reverse logistics is more difficult due to its attributes.

B Volumes are equal to the forward logistics system. Reverse logistics is typically work that happens after a product or service is delivered. D Reverse logistics systems usually use the same processes and players that comprise the forward.

Army Regulation 7117 Supply Chain Management describes reverse logistics as the process by which a product is returned to some point in the distribution. A surge in returns. 2 Reverse logistics systems usually use the same processes and players that comprise the forward-based system.

By LM Staff April 30 2019 scmr_abstract Download Now. An excellent example of a successful reverse logistics system is Apple. Asked Jun 2 2016 in Business by WilsonDyke.

Mainly reverse logistics defies the forward-thinking logic thus moves backward through the supply chain making it more complex and difficult because there is. Discovering that focusing on reverse supply chain management is critical to profitability supply availability and improved customer responsiveness. B Reverse logistics systems are usually designed to be less flexible than forward-based systems.

The importance of reverse logistics is that it ensures profits are maximized waste is minimized and the customer experience is as good as it could be. The Rise of Reverse Logistics in the E-Commerce Freight Shipping World. B Reverse Logistics systems are usually designed to be less flexible than forward-based systems.

The objectives of reverse logistics are to recoup value and ensure repeat customers. Businesses who have implemented the reverse logistics strategy are able to enjoy lower costs better customer service limit their environmental impact and become conscious corporate citizens. Less than 10 of in-store purchases are returned compared to at least 30 of items ordered online.

This can include product returns recycling and exchanges. All sample members were sent an e-mail asking. Effective reverse logistics results in direct benefits including improved customer satisfaction decreased resource investment.

Reverse Logistics Best Practices Download this new whitepaper to learn how to calm the reverse logistics chaos by examining these Distribution Center DC best practices. Warehouse in the News ID Logistics signals. Download this new whitepaper to learn how to calm the reverse logistics chaos by examining DC best practices including.

The study was conducted to better understand how organizations are handling their reverse logistics operations and the challenges top managers face in managing reverse logistics procedures. It is defined as the process of planning implementing and controlling the efficient cost-effective flow of raw materials as well as in-process inventory finished goods and information from the beginning of the supply chain to the end. Have a robust gate-keeping function that gathers information and applies rules-based processing as early as possible in the lifecycle of a return.

A The goods tend to be small in quantity.

Reverse Logistics 12 Reverse Logistics Is Becoming An By Shippr Medium

Comments

Post a Comment